Water Conservation: Key to Sustainable Food Processing

Introduction

The global water sector is responsible for almost 10% of greenhouse gas emissions worldwide. Reducing the carbon footprint of water-related activities or decarbonizing the water business, is a crucial component of global efforts to address and lessen the effects of climate change. In the 28th meeting of the Conference of the Parties (COP 28), at least 20 countries agreed to completely decarbonize their water and wastewater services by 2050. (UNFCCC). The world is now more aware about carbon footprint of food but the same importance is not attached to carbon footprint of water. However, for climate-resilient water and food systems to thrive, integrated management is essential for balancing trade-offs and enhancing synergies between water and food production.

70% of total water expenditure is due to activities related to the food industry (FAO, i7959e). In fact, the activity that consumes it in the highest proportion is agriculture and livestock farming. By 2050, there will likely be more than nine billion people on the planet, which will put a tremendous strain on freshwater resources due to the increased food needed to feed them. By 2035, it is predicted that the world’s water withdrawal will increase by 53%, from 4,500 billion m3/year to 6,900 billion m3/year.

If water usage in the production of food and drink is not more efficiently managed globally, there could be serious consequences, including increased food costs, shortages, pollution, starvation, social discontent, and unstable geopolitical conditions. It has been said that a “world water war” could result from this.

In food manufacturing, there is potential to save blue water and grey water.

- Blue Water: water that is accessible for human use, such as drinking, agriculture, and industrial purposes.

- Grey Water: wastewater generated from food manufacturing processes and cleaning-sanitization. By treating and recycling greywater, we can reduce the strain on freshwater resources.

How can the food industry benefit by conserving water?

- Cost saving: Water is a finite resource whose cost is steadily rising.

- Competitiveness: When there is a shortage or restriction, it is possible to remain competitive (financially and productively) because urban supply will take precedence over agricultural uses and industrial processes, if any restrictions are placed in place.

- Corporate reputation: Taking care of the environment through effective water management shows a company’s social responsibility, has a positive impact on both the sense of belonging of employees and on the external reputation

- Certification: Setting up an environmental management system in accordance with ISO 14001.

What are the areas of significant water consumption in the food industry?

- Agriculture

- Pre-processing: washing of raw material

- Processing: heating and/or cooling, steam production etc.

- Cleaning and sanitation of tools and machinery.

In food manufacturing, water scarcity can be tackled: reduce, recycle, treat before disposal and by finding alternatives.

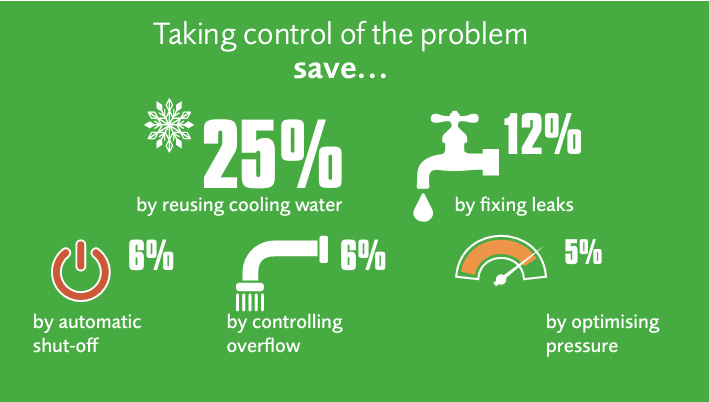

Strategies for reducing water:

- Reusing cooling water

- Resolving leaks and water flow

- Automatic deactivation

- Overflow control

- Supply pressure optimization

Recovery measures to conserve water:

By optimising of existing processes, improved understanding and the research and development of novel process solutions, water can be conserved without compromising food quality and safety in any way. The following measures can help conserve water in food manufacturing:

- Conduct water audit- measuring and reporting the water footprint of the products and processes, can identify peak times, locations which are using more water, leaks.

- Equipment modification- minor changes in the machinery can have a big impact (for e.g.: replacing tap from high volume to high pressure and low volume can lower water consumption)

- Inspect equipment and systems- regular maintenance and inspections prevent leaks and malfunctions from increasing usage.

- Install water saving equipment- using triggers, software to stop water flow, tap aerators, nozzle restrictors

to reduce water flow and pressure wherever possible without affecting performance can save water.

- Replacing antiquated machinery with environmentally friendly fixtures that maximize water use, allowing water to be treated and/or reused.

- Recirculating water- water can be recycled inside the same process if it does not contain excessive amounts of contamination after specific stages of the production process (such as material transportation, air purification, or product or machinery washing). This can be accomplished by installing a piping system with a basic sanitation procedure.

- Going waterless- water is a resource that is essential for food production. Certain processes, nevertheless, can function without water. There are waterless methods that work well in areas that require a lot of water otherwise. Vacuuming and other dry procedures, for example, could remove or drastically reduce the need for water washing. Similarly, the usage of high-pressure hoses could be replaced by mechanical cleaning products.

- Install Low-Flow Fixtures – This technology restricts excessive resource consumption without compromising pressure. It pushes water through a fine screen, adding air to increase the force of the stream.

- Rainwater harvesting- a system that collects rainwater and directly sends it to low-quality systems like toilets.

- Currently these modern technologies are used in food industry to recover water:

- Ozone disinfection- works by dissolving ozone into water and through the ensuing oxidation of bacteria and other waterborne pathogens.

- Cyclone Dirt Separation filtration technology – method of removing particulates from air, gas or liquid stream, without the use of filters, through vortex separation.

- Reverse Osmosis – utilizes pressure to force pure water through a semi-permeable membrane while concentrating salts and other dissolved solids on the feed side of the membrane. However, one of the biggest disadvantages to reverse osmosis is wasted water. Studies show it can waste between 3 and 20 times as much water as they produce.

- Electro-deionisation- Ion exchange resin, ion exchange membranes, and DC power are the three components of the electrodeionization (EDI) water treatment method, which deionizes water. EDI is commonly utilized in the production of ultrapure water as a polishing procedure after reverse osmosis (RO). It operates continually without chemical regeneration.

- Water footprint assessment and reporting- it is crucial for companies to set goals and monitor results to ensure accountability and process.

Conclusion

Governments are mandating water resource tax policy in most countries. There have been efforts to provide financial assistance in setting up clear technology and financial incentives are given based on conservation attempts. “Polluters Pay Principle” has also come into picture where companies that do not conserve/ treat water will pay more tax. (MOHUA). Thus, companies are more likely to make efforts in conserving natural resources.

Companies can lessen their water footprint by using less water internally and eliminating all forms of water contamination. The blue water footprint can be zero if there is no evaporation. The grey water footprint can be eliminated by treating the wastewater that is still created and by minimizing the amount of wastewater that is produced. The company’s own facilities or a public wastewater treatment facility can handle the treatment; the final water quality that is released into the ambient water system determines the grey water footprint.

Conserving water isn’t just about minimising the environmental impact, it can also reduce operating costs. It is also a powerful marketing tool to improve brand image as more consumers are now interested in supporting sustainable businesses. Although it requires significant initial investments, companies can shrink their water footprints and increase their sustainability levels by adopting these waste management strategies.

Author

Connect with Authors at: E-mail foodbiz@sathguru.com

Grow Beyond

Grow Beyond