Pulsed Electric Field (PEF) Technology – Emerging Non-Thermal Food Technology

INTRODUCTION:

Pulsed Electric Field (PEF) technology is rapidly gaining traction in food processing as a non-thermal, energy-efficient alternative to traditional thermal processing methods. PEF improves microbial safety while preserving food flavor, nutrients, and texture, making it an attractive solution for manufacturers striving to meet the increasing demand for healthier, minimally processed products. It is particularly popular in chips, olive oil, beverages, and plant-based products, providing effective microorganism inactivation without high temperatures that can degrade quality. By enabling the production of clean-label, preservative-free products, PEF aligns with consumer preferences for healthier options. As industries focus on sustainability and efficiency, PEF provides a scalable solution to modern challenges. Businesses adopting this technology can enhance product quality, streamline operations, and stay competitive in an evolving market.

PEF TECHNOLOGY AND PRINCIPLE:

PEF technology is a non-thermal food processing method that uses high-voltage electric pulses (typically ranging from 10 kV/cm to 80 kV/cm), causing electroporation in the cell membranes. Parameters such as field strength, pulse frequency, and exposure time can be adjusted to obtain desired outcomes in terms of microbial inactivation or texture modification.

APPLICATIONS OF PEF TECHNOLOGY

This article highlights how PEF is reshaping the food and beverage sector, its key benefits, and how it is being applied to drive efficiency, sustainability, and product innovation.

Due to the ion content, foods and beverages are electrically conductive. PEF technology offers significant advantages in food processing by utilizing electrical fields to enhance product quality and shelf life. The electric field disrupts the cell membranes of microorganisms by generating pores, inactivating bacteria & yeast and extending product shelf life.

PEF controls enzymatic activity by potentially inhibiting spoilage-related enzymes while preserving beneficial ones that enhance texture and nutritional value, thereby maintaining freshness, flavor, and appearance, making it an effective solution for efficient and high-quality food production

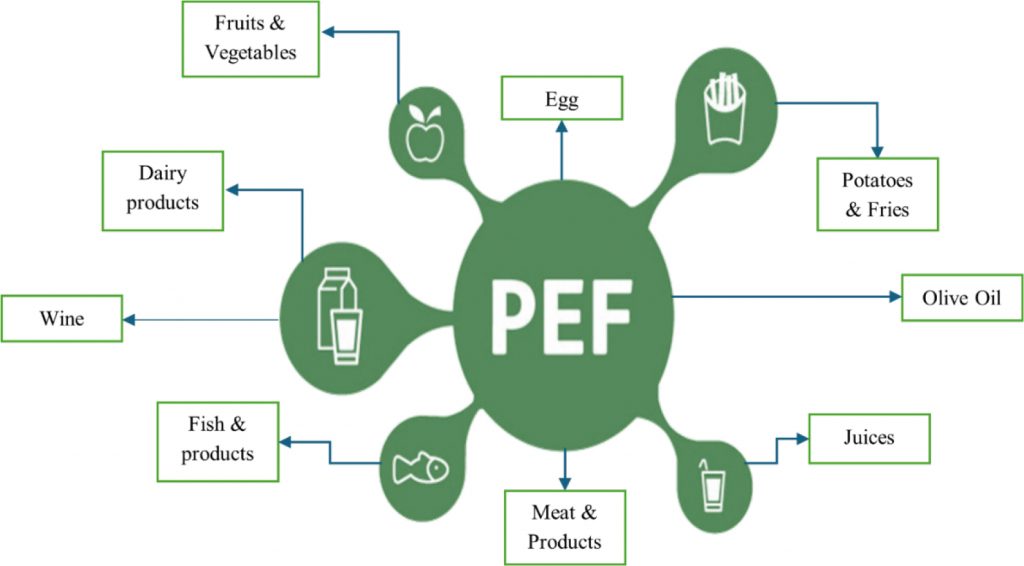

PEF finds applications in various sectors of food & beverage processing, as presented in Figure 1.

INDUSTRIAL ADOPTION OF PEF TECHNOLOGY

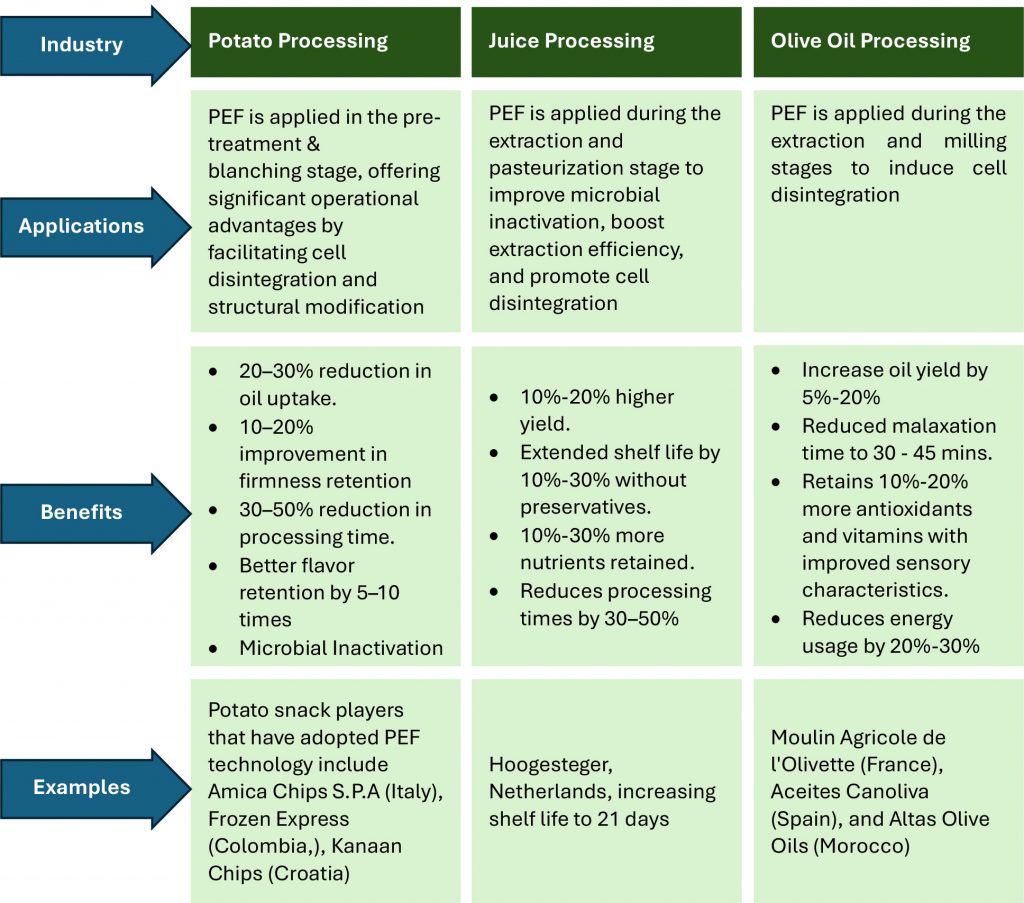

PEF technology is emerging across various food applications, with notable success in product categories such as potato chips and fries, fruit juices, and olive oil. Its successful implementation in these product categories highlights its ability to enhance production processes, improve product quality, and offer valuable business opportunities.

In addition to the above, PEF technology is being trailed in the Dairy, Liquid Egg, Meat, Seafood and Wine industries.

In addition to the above, PEF technology is being trailed in the Dairy, Liquid Egg, Meat, Seafood and Wine industries.

Commercial PEF processing systems for solid food products (in the capacities of 1 T/Hr – 100 T/Hr capacity) and liquid products (400 L/Hr – 6000 L/Hr capacity) are currently available. Elea Technologies (Germany), Pulse Master (Netherlands), Opticept (Sweden), Energy Pulse Systems (Portugal), and Cool Wave Processing B.V. (Netherlands) are major suppliers of PEF systems.

PEF TECHNOLOGY IN INDIA

PEF technology in India is in the research phase, with very limited commercial adoption. The main barriers to widespread implementation include the high capital investment required for specialized equipment and energy management systems and the need for infrastructure capable of handling high-voltage electric fields. These requirements pose a significant financial burden, particularly for small and medium-sized enterprises (SMEs) in the food processing sector. However, PEF presents a substantial opportunity for the food & beverage industry in addition to a significant increase in yield and better-quality products. Processors could see an ROI in 2 to 3 years, which is achieved from their energy savings, thereby aligning with the industry’s shift towards healthier, more sustainable food options.

CONCLUSION:

PEF technology is emerging as a highly versatile and innovative alternative to traditional processing methods, offering distinct advantages, particularly in its non-thermal, energy-efficient, and quality-preserving characteristics, ensuring cost-effectiveness (with ROI being 2 to 3 years) and sustainability.

Author

Connect with Authors at: E-mail foodbiz@sathguru.com

Grow Beyond

Grow Beyond